What is Siloxane? How is Siloxane Separated from Biogas and Landfill Gas?

What is Siloxane?

The term siloxane is derived from the combination of silicon, oxygen, and alkane. Siloxanes are liquid and volatile compounds. Broadly defined, siloxane refers to a group of compounds with the formula R2SiO. Siloxane compounds, through cleaning and cosmetic products, mix into trash and water, manifesting in biogas production. If not separated, they can damage gas engines and tend to be persistent in the environment.

Siloxane compounds are found in cosmetics, deodorants, water-repellent windshield coatings, and food additives. They are primarily used as chemical building blocks for silicone-based rubbers and oils to soften cosmetic products. Additionally, they can serve as waterproof coatings on surfaces like bricks and walls in the construction sector.

What are the Types of Siloxane?

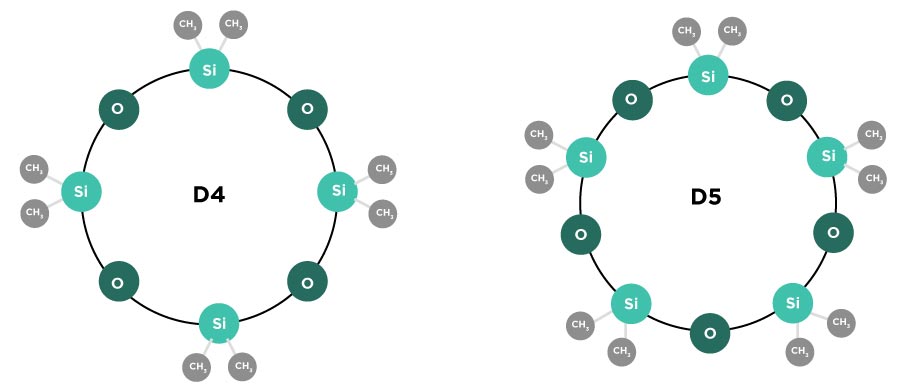

Siloxane components are known to be present in solid waste storage areas, sludge treatment, and biogas. The types of siloxane found in landfill gas are as follows:| Code | Chemical Name |

| L2 | Hexamethyldisiloxane |

| D3 | Hexamethylcyclotrisiloxane |

| L3 | Octamethyltrisiloxane |

| D4 | Octamethylcyclotetrasiloxane |

| L4 | Decamethyltetrasiloxane |

| D5 | Decamethylcyclopentasiloxane |

| D6 | Dodecamethylcyclohexasiloxane |

| L5 | Dodecamethylpentasiloxane |

What are the Effects of Siloxane on Gas Engines in Energy Production?

During biogas production, siloxanes are among the main components that damage gas engines. Siloxane compounds erode the internal parts of machines, shortening their lifespan and increasing operating costs due to repeated oil changes and internal parts replacements. During combustion, siloxane molecules break down, releasing oxygen and silicon. Eventually, silicates accumulate on cylinder heads and valves, combining with other crystal compounds, causing damage to the engine.

What are the Sources of Siloxane?

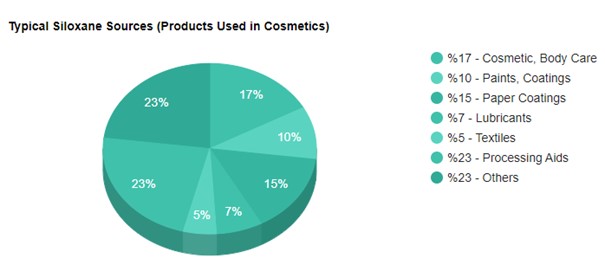

Siloxane components generally form as a result of anaerobic decomposition or fermentation and are found in biogas. Typical sources of siloxane include:- Cosmetics and Care Products (%17)

- Paints and Coating Materials (%10)

- Oils (%7)

- Paper Coatings (%15)

- Food Processing Aids (%23)

- Textile Products (%5)

How is Siloxane Separated?

Various techniques exist for separating siloxane components. Commonly, methods like extreme cooling, specific resin types, and washing with specific reagents are used. The installation and operating costs of separation and filtration systems are high. The most frequently used methods are adsorption with activated carbon and the Anka Regenerative siloxane removal system adsorption technique.

How is Siloxane Separated from Landfill Gas and Biogas?

The two most common methods for separating siloxane from landfill gas and biogas are adsorption with activated carbon and the Anka Regenerative siloxane removal system adsorption technique. Activated carbon is a filter material with a large surface area. The Anka Regenerative Siloxane Removal System offers an effective purification process through a regenerative method, developed by Anka Renewable Energy. This system significantly enhances the performance and lifespan of engines used in biogas production and also greatly reduces the costs of spare parts. Its molecular structure allows it to be easily scaled to any capacity and has the advantage of low pressure drop, which leads to long-term energy savings.

Anka Renewable Energy has successfully implemented numerous projects in Turkey, Bulgaria, Philippines, Russia, and Greece. This system helps prevent the unwanted effects of siloxane components in gas engines. In biogas production, siloxanes from cosmetic detergents that mix with waste, garbage, and water, if not filtered, crystallize with heat in the combustion chamber of the gas engine, causing deformation and wear, and reducing the life of engine oil.

Other products and systems used for the separation of siloxane from biogas and landfill gas include flares, hydrogen sulfide (H2S) removal systems, biogas field well and piping equipment, landfill gas and biogas engine spare parts, gas pressurization (booster) systems, orc heat recovery boilers, automation systems and panels, and gas dryer chiller units.

The use of these technologies not only increases the efficiency of biogas and landfill gas production facilities but also helps reduce their environmental impact. Therefore, the use of these systems is an important part of the overall efforts toward sustainable energy sources. Anka Renewable Energy's work in this area provides innovative solutions in the energy sector, offering both environmental and economic benefits.

-

Comparison of Regenerative Siloxane Removal Systems (SGS) and Activated Carbon

-

Effects Of Siloxane On Engines And Resulting Damages

-

Optimization of Landfill Gas Production Using Vacuum Regulator

-

Problem Solving Technique and Systematics for Engineering Projects

-

What is Siloxane? How is Siloxane Separated from Biogas and Landfill Gas?

-

What are the methods for waste separation (separating as metal, paper, plastic)?

-

Sakarya Biogas Regenerative Siloxane Removal System

Completed -

Sakarya Landfill Gas Regenerative Siloxane Removal System

Completed -

SUEZ Çanakkale Landfill Gas Regenerative Siloxane Removal System

Completed -

Osmaniye Landfill Gas Regenerative Siloxane Removal System

Completed -

Russia/Kulakovskiy LFG To Electricity Plant

Ongoing -

Seymen Landfill Gas Regenerative Siloxane Removal System

Completed -

Kastamonu Landfill Site Rehabilitation Project

Completed -

Edirne Landfill Gas Regenerative Siloxane Removal System

Completed -

Ravda/Bulgaria Landfill Site Rehabilitation Project

Completed -

Aitos/Bulgaria Landfill Site Rehabilitation Project

Completed -

Misamis Oriental WWTP Project - Philippines

Completed -

Manisa Landfill Gas Regenerative Siloxane Removal System

Completed -

Greece/Psyttalia Wastewater Treatment Plant Regenerative Siloxane Removal System

Completed -

Kayseri Landfill Gas Regenerative Siloxane Removal System

Completed -

Botek Arge Kimya Hydrogen Flare

Completed -

Mersin Landfıll Gas Regeneratıve Sıloxane Removal System

Completed -

Silifke Landfıll Gas Regeneratıve Sıloxane Removal System

Completed -

Tetst